Stainless Steel Strips

Stainless Steel Strips

Poongsan Special Metal Corporation (PSM) stainless steel strip products are recognized as the world’s-best products with precision dimensions, accurate mechanical properties, and superior flatness.

Production Scope

Gauge

0.03mm-1.5mm

Width

3-425mm

Tolerance

According to KS D 3698, 3534, JIS 4305, 4313. The others can be manufactured by the customer requirement.

Temper

- Cold rolled: Products can be manufactured by mutual agreement with customer.

Surface finish: DF, BF, PF, Dull, Dura Finish

Mechanical properties

| Guide | Temper | Hardness (Hv) |

Yield Strength (N/㎟) |

Tensile Strength (N/㎟) |

Elongation (%) |

|---|---|---|---|---|---|

| STS301-CSP | |||||

| 1/2H | 310≤ | 510≤ | 932≤ | 10≤ | |

| 3/4H | 370≤ | 745≤ | 1,128≤ | 5≤ | |

| H | 430≤ | 1,030≤ | 1,324≤ | - | |

| EH | 490≤ | 1,275≤ | 1,569≤ | - | STS304-CSP |

| 1/2H | 250≤ | 471≤ | 785≤ | 6≤ | |

| 3/4H | 310≤ | 667≤ | 932≤ | 3≤ | |

| H | 370≤ | 883≤ | 1,128≤ | - |

Stainless Steel Strip for Spring Capability

PSM’s products have excellent elastic limit value, fatigue strength, and creep resistance through stainless steel rolling and heat treatment technology accumulated for more than 30 years. They also have superior precision in thickness control, low distribution of mechanical properties, and superior flatness and mechanical properties. Therefore the products are widely used in components for mobile products, electronic parts, and automobile parts that require spring properties.

Main application

Various terminals, automobile gasket, brake lining, semiconductor clip, mobile phone hinge, mobile phone bezel, connector, LCD frame

Major steel type

301, 304, 304L, 305, 316L, 430, etc.

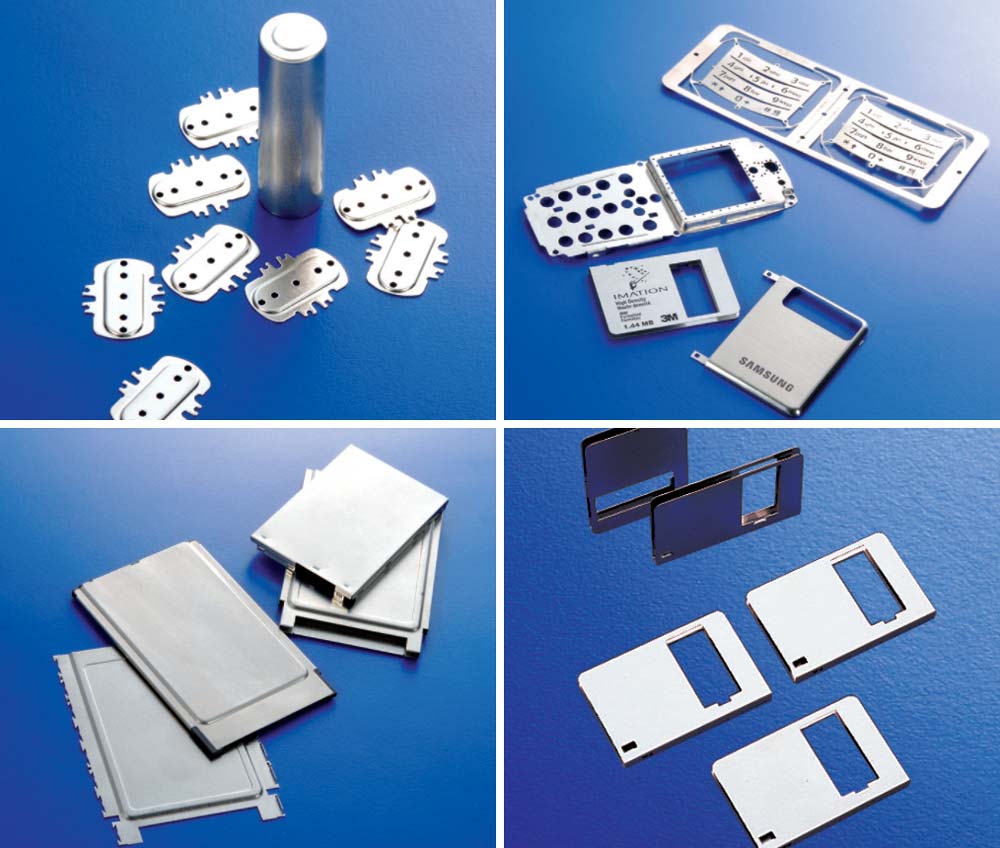

Stainless Steel Strip for IT and Display Devices

PSM produce various high precision and advanced function stainless steel strips that meet the needs of customers for components for electronic guns, small LCDs, switches, connector parts, frames for recently increasing large scale LCD monitors, and hard disk components with high-precision stainless processing technology.

Main application

LCD frame, mobile phone hinge/case/keypad/connector/bezel, plug, antenna, vibration motor, secondary cell, speaker, electrode of electronic gun, tri-metal, etc.

Major steel type

301, 304, 304L, 305, 201, 202, etc.

STS and Special Alloy Foil

PSM is a leading manufacturer of STS and special alloy foil, and produces the best quality ultra thin gage strips that are required for various high-precision electronic components for high strength and high corrosion resistant applications, with the best technological power in the industry and the latest foil manufacturing equipment.

Main application

Automobile anti-pad, gasket for mobile phone, dome switch, honeycomb, various gauge, etching components, fuel filter, etc.

Major steel type

301, 304, 430, etc.

Special Surface Treated BF, DF, PF

PSM produces various surface treated stainless steel strips such as BF, DF, and PF that meet the requirements of the products for functional and processing capability improvement as well as an elegant exterior look.

Main application

Exterior of digital camera, mobile phone keypad, mobile phone battery, diskette core, mobile phone case, electrode of electronic gun, HDD cover, etc.

Major steel type

301, 304, 304L, 430, etc.

Special Heat Treated MA, TA

PSM produces tension annealing treated stainless steel strips used in advanced function and high-precision components as well as managing treated high-strength products with the development of PSM's own heat treatment method and introduction of new facilities.

Main application

The hardness (held) of spinning and weaving machine, reed of spinning and weaving machine, parts for etching blades, high-precision press components, dome switch, HDD components, copier/printer components, etc.

Major steel type

420N1, 420J2, 304, 301, etc.

Usage for Stainless Steel Strips

| No | Alloy | Finish | Size | End-Usage | Remarks |

|---|---|---|---|---|---|

| 1 | Incoloy 840 | BA | 0.46 x 23.7 | Pipe for sheath heater | |

| 2 | 430 | BA | 0.5 x 49.5 | Mold for car | |

| 3 | 304 | CSP-TA | 0.25 x 126 | Back plate for mobile phone | |

| 4 | 301 | H | 0.3 x 325 | Spring for car | |

| 5 | 304L | BA | 0.5 x 58.8 | Pipe for boiler | Low carbon |

| 6 | 304 | 3/4H | 0.8 x 45 | Ejection pin for mobile phone | |

| 7 | 304 | CSP-TA | 0.25 x 145 | Back plate for mobile phone | |

| 8 | 301 | 3/4H | 0.6 x 400 | Spring for car | |

| 9 | 301 | 3/4H | 0.4 x 70 | Brake parts for car | |

| 10 | 304 | 3/4H | 0.4 x 350 | Bezel for mobile phone | |

| 11 | 301 | CSP-TA | 0.25 x 452 | Engine gasket | |

| 12 | 301 | 3/4H | 0.5 x 380 | Brake pad spring for car | |

| 13 | 304 | 2D | 0.4 x 94 | Auto pump for car | |

| 14 | 304L | BA | 0.35 x 34.5 | Tube for laparoscopy (medical device) | Low carbon |

| 15 | 305 | BA | 0.4 x 405 | ABS sensor | |

| 16 | 304 | CSP-PF | 0.1 x 27 | Connector for mobile phone | |

| 17 | 304L | BA | 0.18 x 12.7 | Center pin for second battery | Low carbon |

| 18 | 304 | BA-PF | 0.3 x 400 | Frame for mobile phone | |

| 19 | 420J2 | MA | 0.3 x 80 | Heald for spinning machine | |

| 20 | 304 | 1/2H | 0.5 x 228 | Connector for USB | |

| 21 | 301 | CSP-BF | 0.25 x 360 | Engine gasket | |

| 22 | PB | BA | 0.65 x 55.8 | Torque sensor for car | |

| 23 | 304 | 3/4H | 0.15 x 41 | Connector for mobile phone | |

| 24 | 301 | 1/2H | 0.2 x 28 | Connector for mobile phone | |

| 25 | 304 | 3/4H | 0.4 x 86 | Brake cover shim for car | |

| 26 | 304 | BA | 0.3 x 78 | Flexible pipe | |

| 27 | 304 | 2D | 0.25 x 313 | Gasket for car | |

| 28 | 304 | 1/2H | 0.15 x 440 | Frame for mobile phone | |

| 29 | 430 | C | 0.08 x 100 | Anti-pad for car | |

| 30 | 301 | CSP-CF | 0.3 x 29 | Charging connector for mobile phone | |

| 31 | 301 | H | 0.8 x 100 | Frame for glasses | |

| 32 | 445NF | BA | 0.3 x 314 | Flue tube for boiler | |

| 33 | 304L | BA | 0.61 x 26 | Brake sensor for car | Low carbon |

| 34 | 316L | BA | 0.25 x 184 | Cooler for car | Low carbon |

| 35 | Pure Ni | BA | 0.1 x 4 | Tab for secondary battery |

Tolerance on thickness

| Nominal gage (mm) | Normal Tolerance | Special Tolerance | ||

|---|---|---|---|---|

| Under 150 mm | Over 150 mm | Under 150mm | Over 150mm | |

| Under 0.1 | ± 0.005 | ± 0.005 | ± 0.003 | ± 0.003 |

| Over 0.10 to 0.16 | ± 0.015 | ± 0.020 | ± 0.005 | ± 0.008 |

| Over 0.16 to 0.25 | ± 0.020 | ± 0.025 | ± 0.008 | ± 0.010 |

| Over 0.25 to 0.40 | ± 0.025 | ± 0.030 | ± 0.010 | ± 0.012 |

| Over 0.40 to 0.60 | ± 0.035 | ± 0.040 | ± 0.015 | ± 0.015 |

| Over 0.60 to 0.80 | ± 0.040 | ± 0.045 | ± 0.015 | ± 0.018 |

| Over 0.80 to 1.00 | ± 0.040 | ± 0.050 | ± 0.015 | ± 0.020 |

| Over 1.00 to 1.25 | ± 0.050 | ± 0.050 | ± 0.020 | ± 0.025 |

| Over 1.25 to 2.00 | ± 0.050 | ± 0.060 | ± 0.020 | ± 0.025 |

Tolerance on width

| Nominal gage (mm) | Under 80 mm | Over 80 to 160 mm | Over 160 to 250 mm | Over 250mm |

|---|---|---|---|---|

| Under 0.16 | ± 0.10 | ± 0.10 | ± 0.10 | ± 0.15 |

| Over 0.16 to 1.00 | ± 0.15 | ± 0.15 | ± 0.20 | ± 0.25 |

| Over 1.00 to 1.60 | ± 0.20 | ± 0.20 | ± 0.25 | ± 0.30 |