Brass Rods

Brass Rods

The best technology and the best choice

Since it was established in 1969, Poongsan has remained the leading company in the Korean copper manufacturing industry and a major player in the global copper industry. With its extensive experience, advanced technology, first-class experts, and new production facilities, Poongsan has contributed to a higher quality of life through the supply of materials to a diverse range of industries.

Onsan Mill

Poongsan operates two copper mills including the Onsan Mill, which is the largest copper processing facility in the world. These mills produce a total of more than 300,000 tons of products annually. After 1990, Poongsan began constructing production bases overseas in the United States, Thailand, Malaysia, and China.

The combined production capacity of these overseas affiliates is 165,000 tons, of which these products are destined for their respective local markets.

Production technology

Poongsan produces a full range of high-quality brass rods and lead free brass bars in its integrated production system. From casting, to chamfering, to inspection under strict quality control procedures, the Company focuses on quality from start to finish.

Furthermore, using state-of-the-art facilities such as a 4,000 ton extruding press with indirect heater, rod blocks, and a combined machine, the company can produce brass rods from 3mm to 90mm in diameter, with high production capability and flexibility. Bars are widely used in bolts and nuts, valves, various machinery and electric parts, and accessory components for automobiles and industrial equipment.

Vertical Continuous Caster

- Vertical continuous casting process has large amount of production and quality improvement.

- V.C.C. capacity is 5,000MT/month.

4,000 Ton Press

- The 4,000 ton automatic extrusion press continuously produces a variety of high quality mother-rods.

2,500 Ton Press

- Specified for brass wire extrusion.

The Newest Combined Drawing Machine

- The newest 6-Shumag combined drawing machines are used for mid- and small-size of brass rod processing.

Eddy Current Tester

- Electromagnetic tester preventing surface failure.

Quality & Delivery

Quality Performance

- Comprehensive laboratory for quality test and improvement

- 6 Sigma for customer satisfaction

- Monthly meeting for quality evaluation

- ISO 9001 Certified since 1993

- ISO 14001 Certified since 2003

Delivery Performance

- Around 30 days after placing order

Packing

Road & Bar

- Wooden box

- Bundle

Standard Production Range

Rod Type

Unit: mm. Diameter tolerance is subject to JIS, ASTM, DIN, and BS.

Length

Unit: mm. Chamfering angle is available

Tolerance of Straightness (Drawing Rod)

Unit: mm.

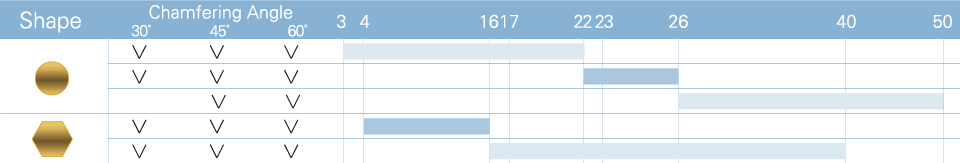

Rod Pointing & Chamfering

Rod Type

Unit: mm. "V": Chamfering angle is available.