Necking & Final Trimming

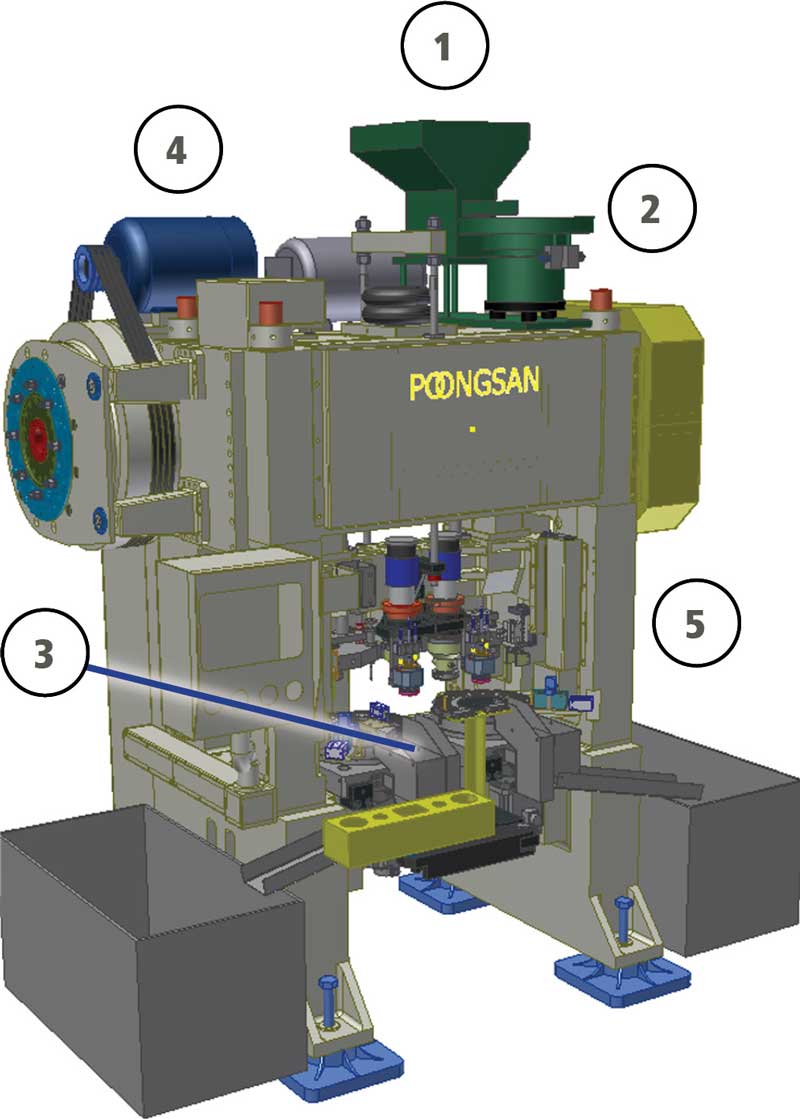

Necking and Final Trimming Machine (NFTM)

Purpose

Efficiently forms cartridge necks and trims cartridge cases to final sizes.

Caliber range

Small arms ammunition

Additional technical data

- Stroke: 120 mm

Machine description

- After heading and head turning processes, cases are fed into index dials.

- Dials run according to an indexed circular motion.

- Cases pass through lubrication, mouth spreading, first and second taper, plug and trimming processes continuously.

- At final inspection, good cases are kept, and defective cases are automatically discharged.

| Specifications | NFTM Option 1 | NFTM Option 2 |

|---|---|---|

| Theoretical rate | 200 parts/min | 100 parts/min |

| Number of spindles | 16 x 2 ways | 16 x 1 way |

| Hourly capacity | Max. 9,600 parts/hr | Max. 4,800 parts/hr |

| Overall dimensions (mm) | 2,000 (L) x 1,260 (W) x 2,300 (H) | 1,400 (L) x 1,300 (W) x 2,400 (H) |

| Net weight | 4,000 kg | 2,000 kg |

Main Features

Dials

- Improve productivity by 2-way supply

- Driven by servo motors, where each motor is dedicated to one dial

Hopper & feeder

- Store more than 3,000 cases

- Equipped with a 2-way supply feeder

| No. | Item | Specification |

|---|---|---|

| 1 | Hopper | Minimizes scratches by using urethane coating |

| 2 | Feeder | Feeds cases into dial |

| 3 | Dials | Operates parts |

| 4 | Main motor | Option 1: 5.5 kW inverter motor Option 2: 2.2 kW inverter motor |

| 5 | Frame | Minimizes strain on the machine because frame is a single cast |